Standard Probes are Cumbersome

- Require time and money for repeated calibration and sterilization

- Block bioreactor ports

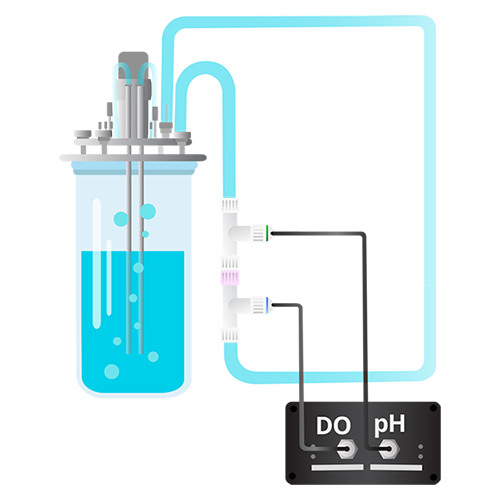

Use flow cells to monitor pH and dissolved oxygen when standard probes are not an ideal fit. Simply connect the flow cells directly into your flow loops (e.g., feeding, sampling or harvesting flow lines for bioreactors) and start measuring. Detect changes in environmental conditions early and ensure a healthy cell culture with around-the-clock monitoring of these critical process parameters.

Key Features

pH ranges: 5-7, 6-8, 7-9

DO range: 0-50% O2 (gas), 0-100% O2 (liquid)

Benefits

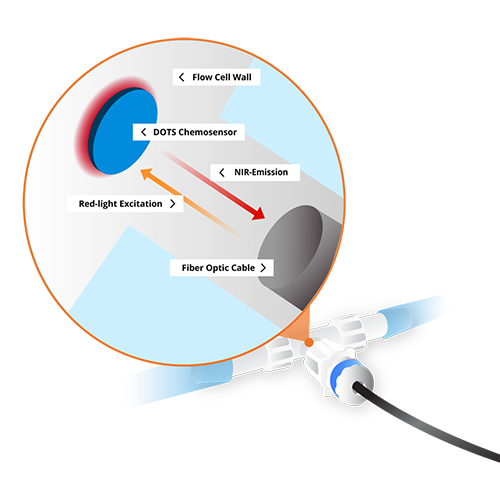

The flow cell is integrated into a flow loop. Chemosensors containing luminescent dye indicators are embedded in a matrix and held inline by the flow cell. The sample travels through the flow cell, passing over the chemosensor. A fiber optic cable is fed into the top of the flow cell, which transmits light between the chemosensor and the fiber optic sensor.

The sensor emits a red light (orange-red at a wavelength of 610-630 nm), exciting the chemosensors which show luminescence in the near infrared region (NIR, 760-790 nm). Depending on the molecules present in the solution, the amount of luminescence changes. The sensor measures this phase shift which is then calculated into the relevant parameter.

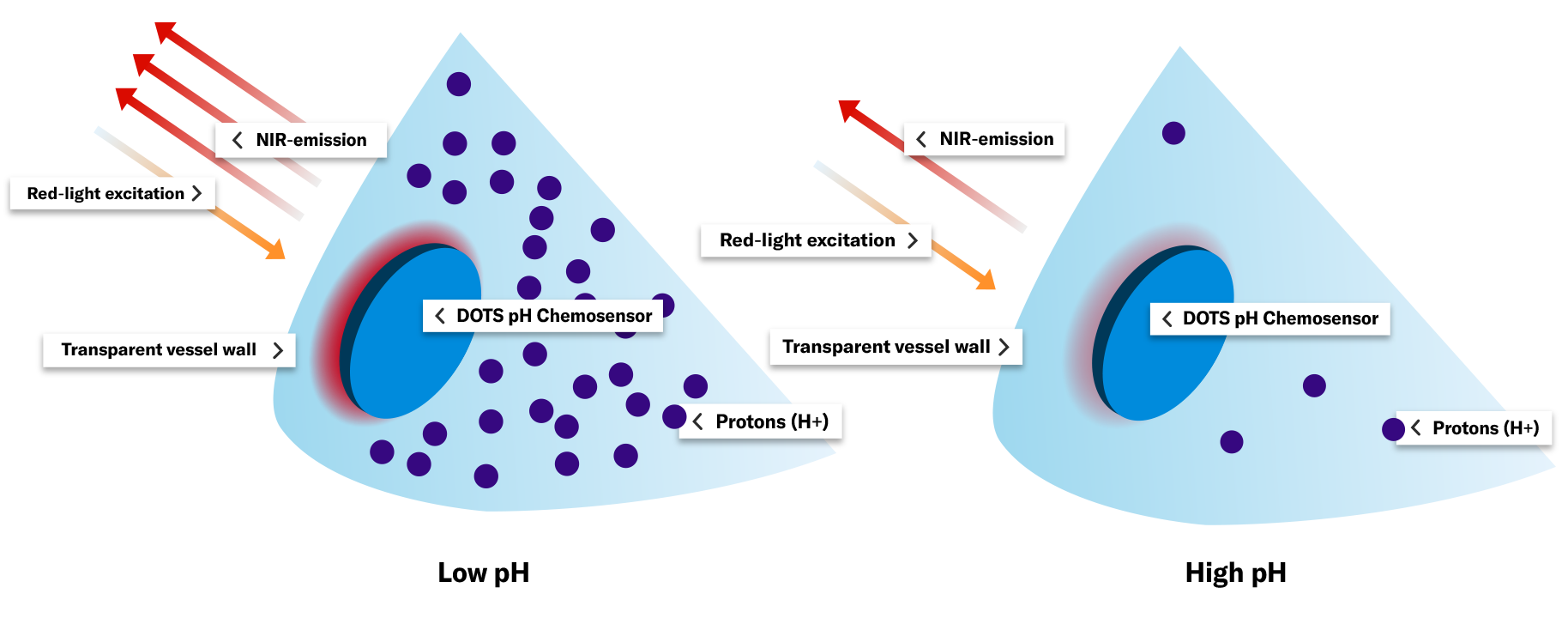

The chemosensor contains both a pH-sensitive indicator and a pH-insensitive reference dye.

At higher pH levels, the pH indicator dye is deprotonated. When the deprotonated chemosensor is excited via red light transmitted from the fiber optic sensor, the luminescence of the pH-sensitive indicator is quenched and only the NIR emission is measured. As the pH lowers, the sample becomes more acidic and the pH indicator becomes protonated. In this state, when the sensor emits red light, the indicator emits bright NIR luminescence.

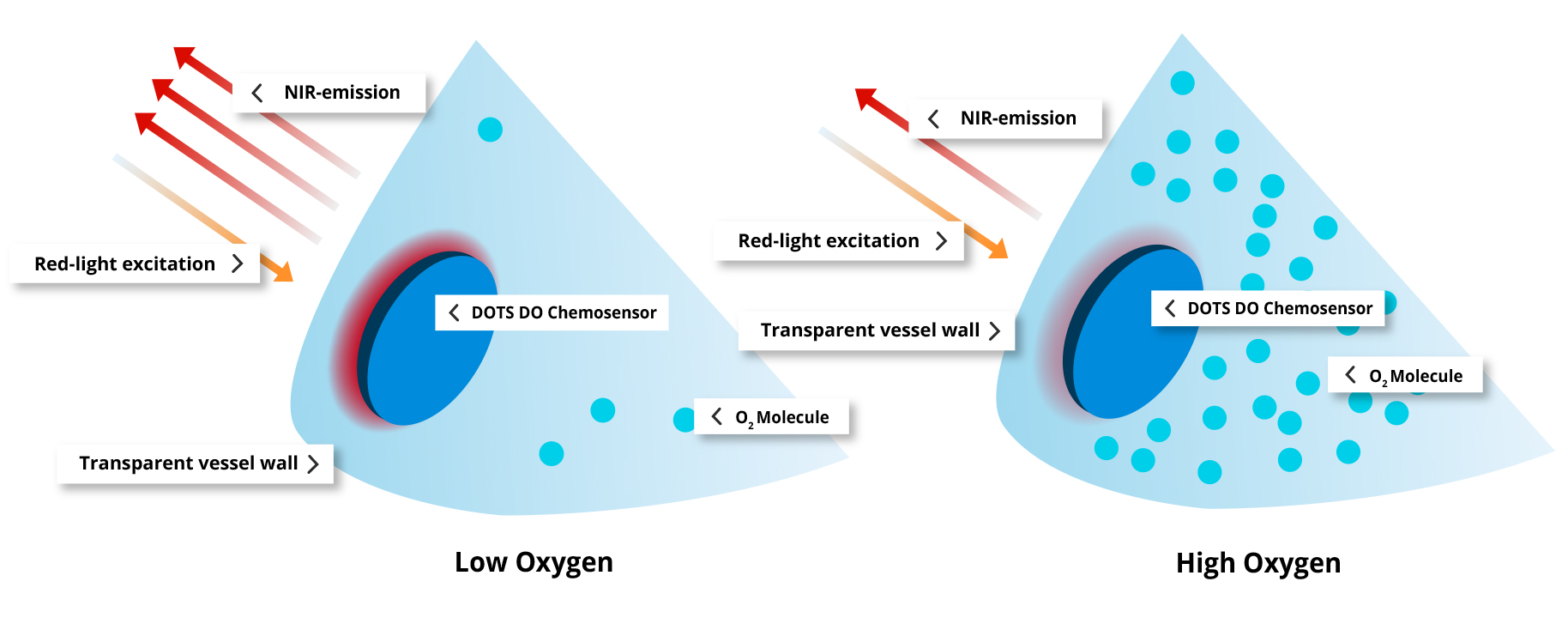

This chemosensor contains an oxygen-sensitive indicator.

When the sensor emits red light, the indicator shows bright luminescence in the NIR range. At low concentrations of dissolved oxygen, there is less collision between oxygen molecules and the indicator dye, allowing for a brighter emission of NIR light. As the oxygen concentration increases, the rate of collision also increases. This collision quenches the luminescence of the oxygen-sensitive indicator, reducing the intensity of NIR-emission.

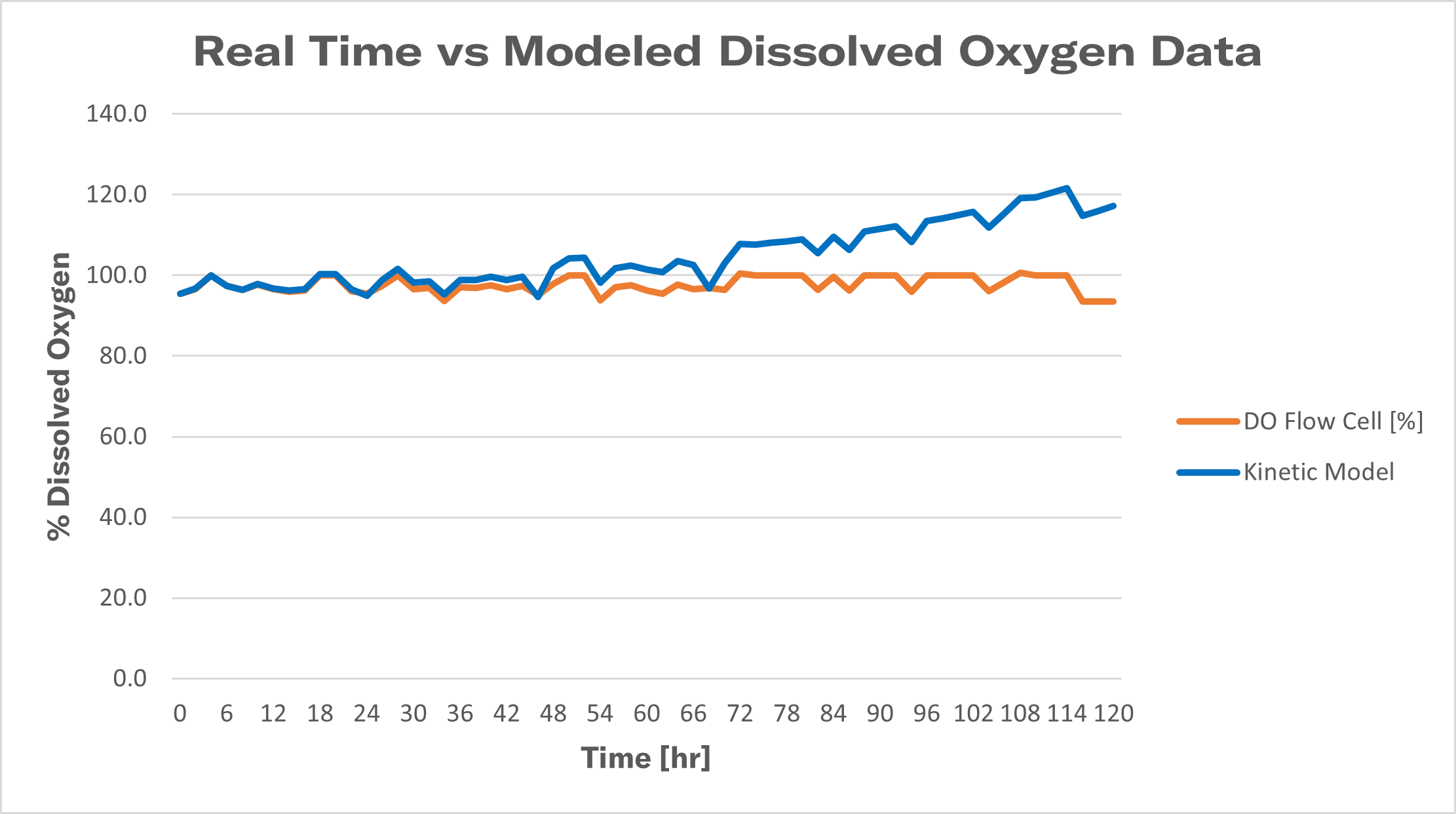

CD8 Cytotoxic T Cells, Modified-COBE® Benchtop Centrifugal Bioreactor,

Improve your bioprocess with real-time information. Dissolved oxygen data showed an average of 5% higher levels than those anticipated by the kinetic model (based on oxygen consumption rates from static culture studies). This outcome suggests that cells might not be using oxygen as rapidly as previously believed. It raises the possibility that the unique dynamics within the bioreactor, such as centrifugal and fluid forces, could be influencing the oxygen consumption patterns of the cells.

Single-use flow cells with integrated chemosensors for pH or dissolved oxygen (DO). Each flow cell comes factory-calibrated and pre-sterilized so it is ready to use right out of the box. Luer-lock connectors make is easy to fit to any sized tubing. Combine pH and DO flow cells with a luer-luer adapter and measure both in the same flow loop simultaneously.

Consists of an LED which excites the chemosensor and a photodiode that detects the emission. Light is transmitted between the sensor and the flow cell via a fiber optic cable. The sensor collects the data from all monitored flow cells and sends it to the DOTS Software.

Available in single channel for measuring only pH or DO, or dual channel for measuring both parameters at the same time.

DOTS Software, when paired with a sensor, allows you to monitor critical parameters while your experiment is running. Personalized dashboards allow you to easily visualize data while experimental control features make important information such as calibration offsets and environmental compensation values (temperature, relative humidity, atmospheric pressure and others) easy to include.

| Measurement Type | Liquid – pH |

| Measurement Range | 5-7 pH, 6-8 pH, 7-9 pH |

| Response Time (t90) |

Flow >10 mL/min <90 sec Flow <10 mL/min <120 sec |

| Drift | <0.005 per day at 25°C |

| Shelf Life | 1 year in original packaging at room temperature |

| Recommended Flow Rate | 1-500 mL/min |

| Temperature Range | 0-50°C |

| Pressure Range | 0-2 bar |

| Cross Sensitivity | Organic solvents, charged surfactants |

| Accuracy | +/- 0.05 (after 2-pt calibration) |

| Resolution | 0.003 |

| Detection Limit | <2 pH, >11 pH |

| Measurement Type | Gas – % O2 | Liquid – Dissolved Oxygen |

| Measurement Range | 0-50% O2 | 0-250% air saturation |

| Response Time (t90) | <10sec |

Flow >10 mL/min <20sec |

| Lifetime | 10,000,000 data points | |

| Shelf Life | 3 years in darkness at room temperature | |

| Recommended Flow Rate | 1-500 mL/min | |

| Temperature Range | 0-50°C | |

| Pressure Range | 0-2 bar | |

| Cross Sensitivity | Organic solvents, bleach | |

| Accuracy | At 1% O2: +/- 0.02% At 20% O2: +/- 0.2% |

At 5% air saturation: +/- 0.1% At 95% air saturation: +/- 1% |

| Resolution | At 1% O2: 0.01% At 20% O2: 0.05% |

At 5% air saturation: +/- 0.05% At 95% air saturation: +/- 0.25% |

| Detection Limit | 0.02% O2 | 0.1% air saturation |

Perfusion bioreactors, custom benchtop bioreactors, and small-scale fermenters

On-line flow loops

Harvest lines, sampling lines, media in/out flow lines, waste removal lines

Our team of application scientists will work with you to ensure that our flow cells fit your specific application.

Cell culture expansion

Process characterization

Bioprocess quality control

Harvest of cellular metabolic products

Early contamination detection based on shifts in pH or DO levels

Yes, the Flow Cells are compatible with a variety of cell culture media, including blood.

DOTS Flow Cells come factory-calibrated, and this calibration is recognized by the DOTS Software via the sensor code on the outside of each package. For most users, the factory calibration is sufficient to monitor overall trends in pH and dissolved oxygen (DO). If you’d like to discuss your specific application or determine whether additional calibration would be beneficial, please contact our Service team — they’ll be happy to advise you.

The Flow Cells are single-use devices with integrated chemosensors for DO and pH. Reuse is not recommended, as it will compromise both sterility and system integrity.

| Measurement Type | Liquid – pH |

| Measurement Range | 5-7 pH, 6-8 pH, 7-9 pH |

| Response Time (t90) |

Flow >10 mL/min <90 sec Flow <10 mL/min <120 sec |

| Drift | <0.005 per day at 25°C |

| Shelf Life | 1 year in original packaging at room temperature |

| Recommended Flow Rate | 1-500 mL/min |

| Temperature Range | 0-50°C |

| Pressure Range | 0-2 bar |

| Cross Sensitivity | Organic solvents, charged surfactants |

| Accuracy | +/- 0.05 (after 2-pt calibration) |

| Resolution | 0.003 |

| Detection Limit | <2 pH, >11 pH |

| Measurement Type | Gas – % O2 | Liquid – Dissolved Oxygen |

| Measurement Range | 0-50% O2 | 0-250% air saturation |

| Response Time (t90) | <10sec |

Flow >10 mL/min <20sec |

| Lifetime | 10,000,000 data points | |

| Shelf Life | 3 years in darkness at room temperature | |

| Recommended Flow Rate | 1-500 mL/min | |

| Temperature Range | 0-50°C | |

| Pressure Range | 0-2 bar | |

| Cross Sensitivity | Organic solvents, bleach | |

| Accuracy | At 1% O2: +/- 0.02% At 20% O2: +/- 0.2% |

At 5% air saturation: +/- 0.1% At 95% air saturation: +/- 1% |

| Resolution | At 1% O2: 0.01% At 20% O2: 0.05% |

At 5% air saturation: +/- 0.05% At 95% air saturation: +/- 0.25% |

| Detection Limit | 0.02% O2 | 0.1% air saturation |

Perfusion bioreactors, custom benchtop bioreactors, and small-scale fermenters

On-line flow loops

Harvest lines, sampling lines, media in/out flow lines, waste removal lines

Our team of application scientists will work with you to ensure that our flow cells fit your specific application.

Cell culture expansion

Process characterization

Bioprocess quality control

Harvest of cellular metabolic products

Early contamination detection based on shifts in pH or DO levels

Yes, the Flow Cells are compatible with a variety of cell culture media, including blood.

DOTS Flow Cells come factory-calibrated, and this calibration is recognized by the DOTS Software via the sensor code on the outside of each package. For most users, the factory calibration is sufficient to monitor overall trends in pH and dissolved oxygen (DO). If you’d like to discuss your specific application or determine whether additional calibration would be beneficial, please contact our Service team — they’ll be happy to advise you.

The Flow Cells are single-use devices with integrated chemosensors for DO and pH. Reuse is not recommended, as it will compromise both sterility and system integrity.

Integrated dissolved oxygen flow cells helped optimize a centrifugal bioreactor (CBR) designed to maximize cytotoxic T lymphocyte (CTL) production for use in immunotherapy treatments.