Save Money

Shakes flasks are inexpensive to buy and maintain.

One Parameter at a Time

.png?width=285&height=285&name=for_microbial_and_cell_culture_banner%20(2).png)

Shake flask cultivations are a widely used for both, microbial and cell culture bioprocesses:

Already found in most lab spaces, many experiments rely heavily on the usage of shake flasks. Compared to bioreactors, shake flasks are a low-cost, easy-to-use option for use in a small-scale lab setting.

Shakes flasks are inexpensive to buy and maintain.

Faster setup of experiments frees up time for other things in your day.

More conditions can be tested in parallel, giving you more insight into your process needs.

Easy to integrate into existing laboratory infrastructure.

Working in smaller volumes means using less resources, such as media and nutrients.

While shake flask play a pivotal role in any modern bioprocess lab and team, they do have some significant disadvantages:

Scientists are forced to choose between bioreactors or flasks. There is no solution that combines the advantages of both...until now!

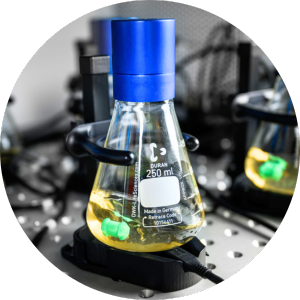

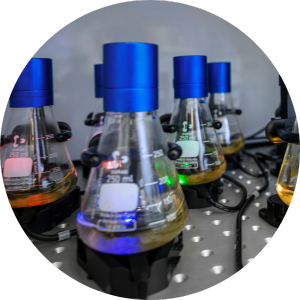

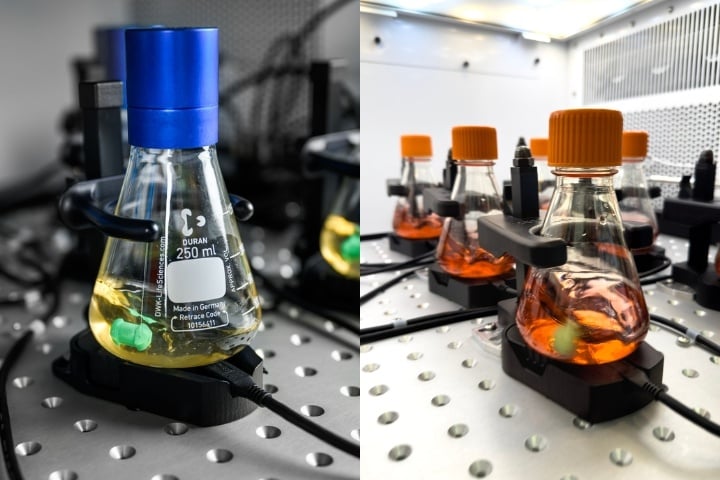

DOTS combines sensors and actuators with a powerful software to create bioreactor-like shake flasks with actionable insights into your bioprocess when and where it matters most.

The DOTS Platform consists of 4 components: Multiparameter Sensor (MPS), Sensor Pills, Liquid Injection System (LIS) & DOTS Software.

The Multiparameter Sensor (MPS) enables the optical and non-invasive monitoring of various process parameters. Currently, the MPS can be used to read out DO Sensor pills and for non-invasive fluorescence and biomass monitoring, utilizing backscattered light detection.

Learn More: MPS

sbi’s Liquid Injection System (LIS) facilitates the automated feeding of liquids into shake flask cultures. LIS enables bioreactor-like options in shake flasks: Fed-batch, DO-based feeding, biomass-based feeding, automated promotor induction, and more.

Learn More: LIS

Sensor Pills are the next generation of chemosensors. Each pill contains a chemosensor for a critical process parameter that then can be read out non-invasively by the Multiparameter Sensor. Currently we offer Dissolved Oxygen (DO) Sensor Pills for real-time DO monitoring in shake flasks.

Learn More: Sensor Pills

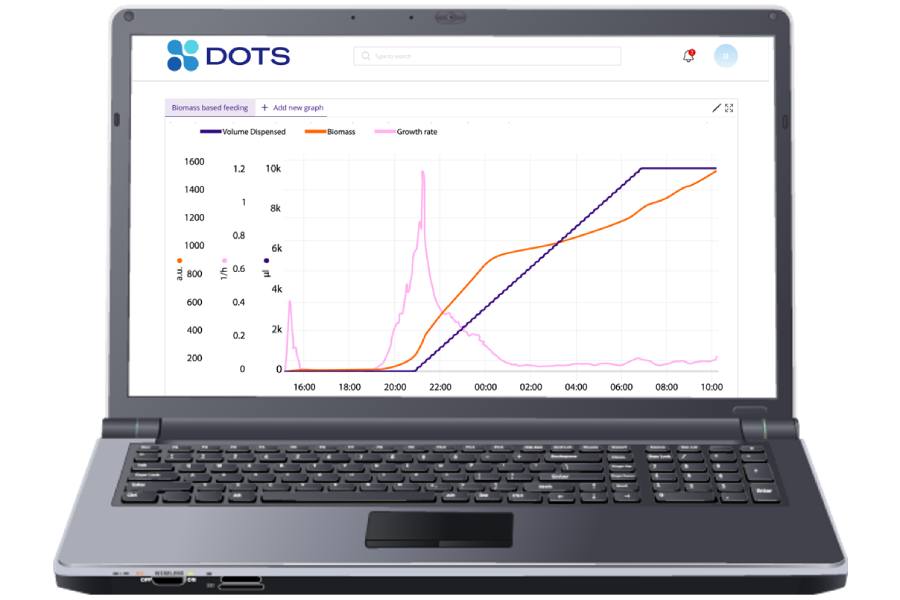

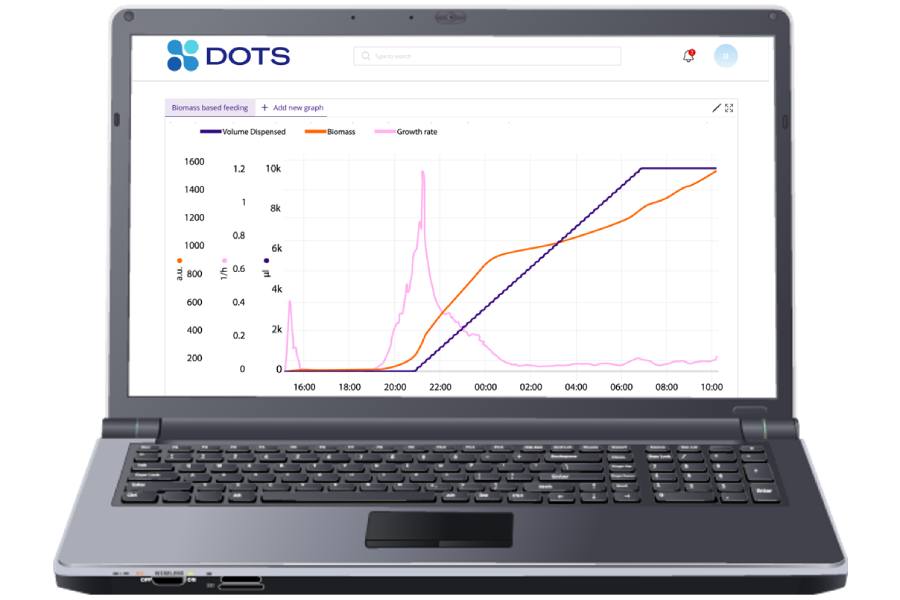

DOTS Software is your tool for easy handling of sensors and actuators, enabling real-time visualization and analysis of multiple parameters in parallel for optimal bioprocess understanding and control.

The Multiparameter Sensor (MPS) enables the optical and non-invasive monitoring of various process parameters. Currently, the MPS can be used to read out DO Sensor pills and for non-invasive fluorescence and biomass monitoring, utilizing backscattered light detection.

Learn More: MPS

sbi’s Liquid Injection System (LIS) facilitates the automated feeding of liquids into shake flask cultures. LIS enables bioreactor-like options in shake flasks: Fed-batch, DO-based feeding, biomass-based feeding, automated promotor induction, and more.

Learn More: LIS

Sensor Pills are the next generation of chemosensors. Each pill contains a chemosensor for a critical process parameter that then can be read out non-invasively by the Multiparameter Sensor. Currently we offer Dissolved Oxygen (DO) Sensor Pills for real-time DO monitoring in shake flasks.

Learn More: Sensor Pills

DOTS Software is your tool for easy handling of sensors and actuators, enabling real-time visualization and analysis of multiple parameters in parallel for optimal bioprocess understanding and control.

Download Microbial Exemplary Data Sets Download Cell Culture Exemplary Data

Monitor biomass and growth rates non-invasively through the vessel wall via backscattered light detection. The real-time, high-resolution growth curves provide actionable insights into your strain's growth behavior.

When combined with the single-use Dissolved Oxygen Sensor Pill, the MPS continuously detects changes in the DO level of your culture.

An integrated spectrophotometer enables fluorescence monitoring of various wavelengths, also in parallel, and evaluation of fluorescent protein expression.

Integrate the MPS with sbi's Liquid Injection System (LIS) to precisely feed liquids based on specified parameters (i.e. DO, biomass). These advanced control options elevate your shake flask experiments to a new level of precision and effectiveness.

Embedded ambient sensors in the MPS enable the measurement of environmental parameters such as temperature, shaking speed, and humidity, providing comprehensive insights into your bioprocess and indicating shaker openings or other disruptions.

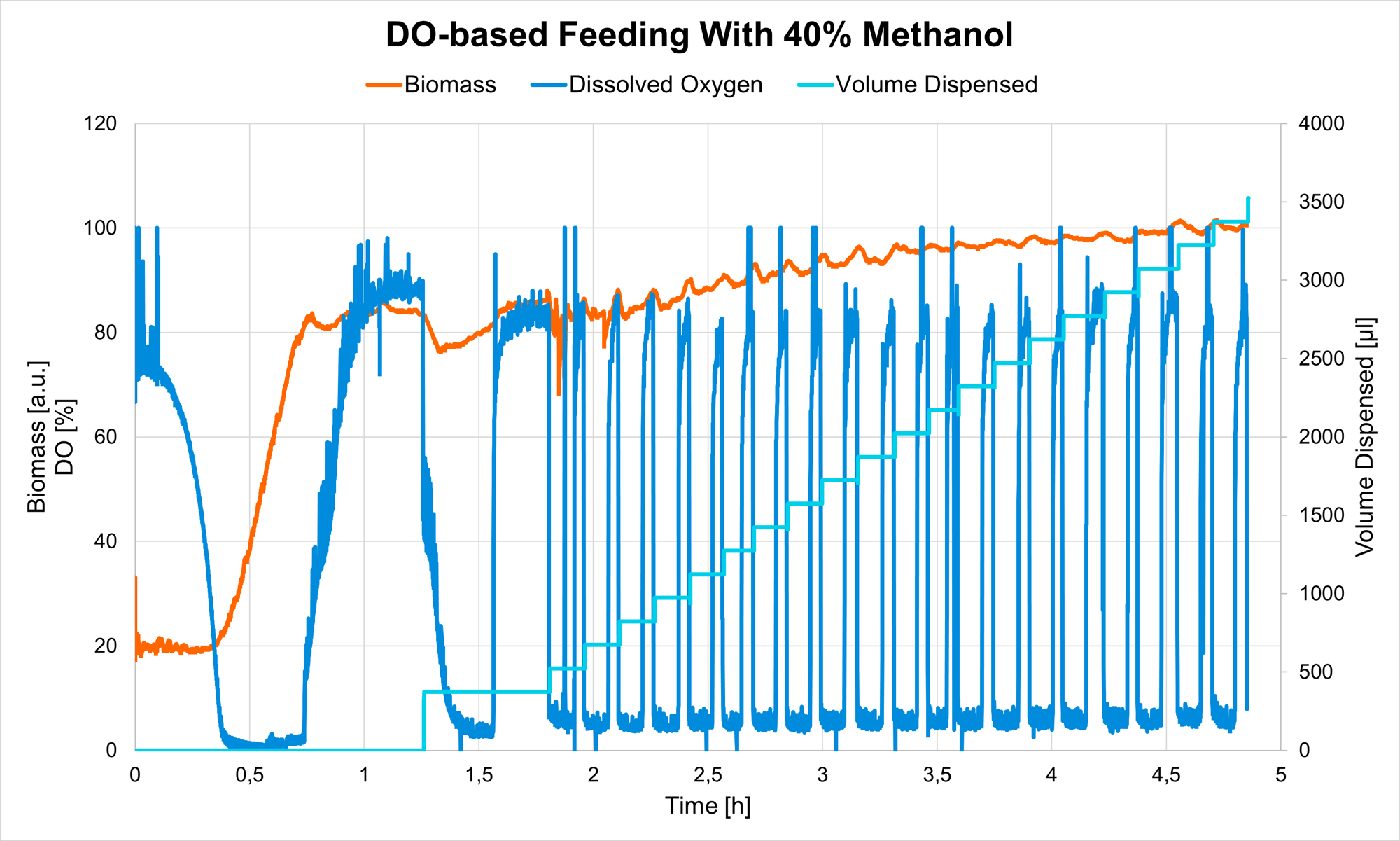

Pichia pastoris (P. pastoris), 200 rpm/25 mm, 10 % filling volume, 250 ml flask, 37°C

With a DOTS-integrated controller, the methanol feed (carried out with the Liquid Injection System) was adjusted to start repeatedly, always when the DO level, monitored by DO Sensor Pills, reached a preset threshold. By using this feature, methanol was always fed as soon as the cells recovered from the previous shot, enabling ideal cell viability, while keeping promotor activity constant. Biomass was monitored additionally, with the Multiparameter Sensor (MPS).

CHO Cell, 0.3 million cells / mL, Nalgene flask, 250 mL, 20% filling volume (50 mL), 150 rpm, 50 mm

Biomass for CHO cells demonstrates strong correlation with offline biomass measurements obtained via Total Cell Density (TCD) analysis. The MPS exhibits exceptional reproducibility when comparing data collected from two independent sensors (Flask 1 vs Flask 2), showcasing its consistency and robustness for process monitoring in bioprocess applications.

More experiments in same time & more knowledge generated from experiments

Less bioreactor runs & less hands-On time per experiment

“Using the DOTS Platform, we were able to gain actionable insights from our CHO shake flask cultivations. This allows us to reduce sampling as important data are given online and in real time.”

DOTS offers the simplest sensor handling in bioprocessing for a broad variety of parameters and applications.

Strain development, screening, and characterization

Bioprocess optimization

Media optimization

Growth characterization (including toxicity tests, substrate-/product-inhibitions, and oxygen-limitations)

Timing of workflows (such as inoculation, induction, sampling, feeding, or harvesting)

Bioreactor-like experiments on shake flask level (e.g., automatized induction, biomass-based fed-batch processes)

DOTS offers the simplest sensor handling in bioprocessing for a broad variety of parameters and applications.

Strain development, screening, and characterization

Bioprocess optimization

Media optimization

Growth characterization (including toxicity tests, substrate-/product-inhibitions, and oxygen-limitations)

Timing of workflows (such as inoculation, induction, sampling, feeding, or harvesting)

Bioreactor-like experiments on shake flask level (e.g., automatized induction, biomass-based fed-batch processes)

.png)