Digitally

Miniaturized Smart Sensors

Powerful Software

There are still too many unknowns in bioprocessing. We help researchers make the right decisions by providing them access to critical process and product data.

A fun group of scientists, engineers, developers, and business people with the goal to make bioprocessing simpler.

We have introduced 'Digitally Simplified Bioprocessing' so you can monitor every point of interest when and where it matters.

Miniaturized Smart Sensors

Powerful Software

Automated and Real-time

Actionable insights

Microbial & Mammalian

Shake Flasks & Bioreactors

Like many good stories, ours began when one researcher pursued his fascination — to connect the environment of the cell with its metabolic behavior — and shared his research with experts and practitioners in the biotech industry. Fluorometrix Corp was formed by Drs. Rao and Joe Qualitz based on fundamental patents on optical sensors for monitoring dissolved oxygen, pH, CO₂, and glucose.

Scientific Industries (SI) – creator of the ubiquitous Vortex-Genie® – acquires Fluorometrix and changes the company name to Scientific Bioprocessing Inc. (sbi). It was the vision of SI’s Chairman, Mr. Joe Cremonese, to combine SI’s expertise in creating optimal cell growth environments with the sbi optical sensor technology to make the lives of cell scientists and bioprocess engineers easier and more productive with a faster trajectory to critical research results.

In 2014, Jens Bayer, Daniel Grünes, Konrad Herzog, and David Frank, a dynamic group of young entrepreneurs and biotechnologists co-founded aquila biolabs and launched the Cell Growth Quantifier (CGQ), which revolutionized biomass monitoring in countless laboratories.

sbi and aquila biolabs join forces and introduce a new era of Digitally Simplified Bioprocessing. Through a combined network of sensors and actuators alongside a powerful software, researchers can gain actionable insights into their bioprocess when and where it matters most.

We offer the DOTS Platform to bring bioreactor-like shake flasks into your laboratory. Advanced sensing and control options in shake flasks allow for simpler handling and lower costs than similar fermentation platforms. Start now and build a smarter shake flask - one parameter at a time.

VP OF MARKETING

& SALES

Discover the difference our technology has made for our customers.

Real-time, actionable insights can have a significant impact on your mammalian cell culture or microbial fermentation experiments and biomanufacturing.

- Prof. Dr. Lars Blank (RWTH Aachen)

- Frédéric Lapierre (HS München)

- Dipl. Ing. Andreas Hoffman (Technical University Dresden)

.png?width=1200&height=600&name=Kopie%20von%20Centrale%20Sup%C3%A9lec%20Image%20(6).png)

- Dr. Victor Pozzobon (Chaire de Biotechnologie, CentraleSupélec)

.png?width=1200&height=600&name=Kopie%20von%20Centrale%20Sup%C3%A9lec%20Image%20(7).png)

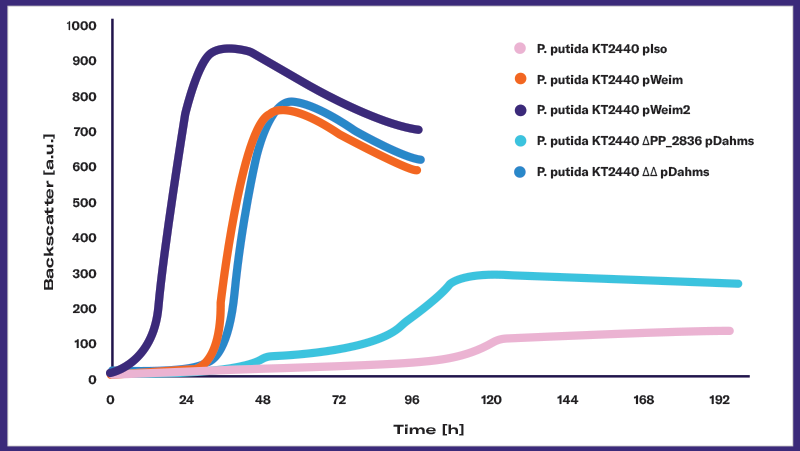

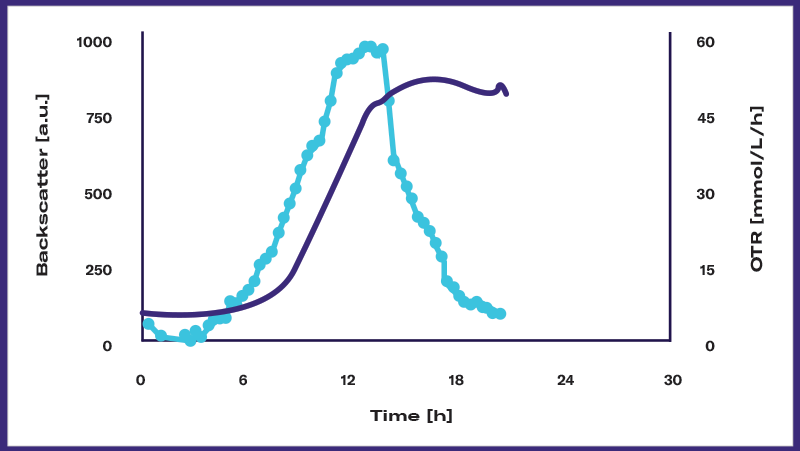

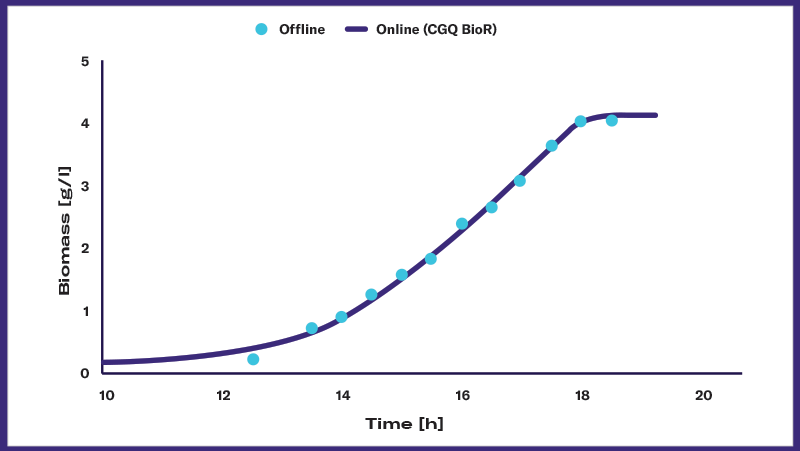

- Dipl. Ing. Robert Klausser (IBD Group, TU Wien)