Bioprocess

- For a broad range of microorganisms (E. coli, yeast, etc...) and cell types (CHO, HEK)

- For most media compositions

First pill-based and nanoparticle optical sensor for online dissolved oxygen (DO) monitoring in shake flasks.

-1.png?width=300&height=115&name=Part-of-DOTS%20(1)-1.png)

.png?width=285&height=285&name=for_microbial_and_cell_culture_banner%20(2).png)

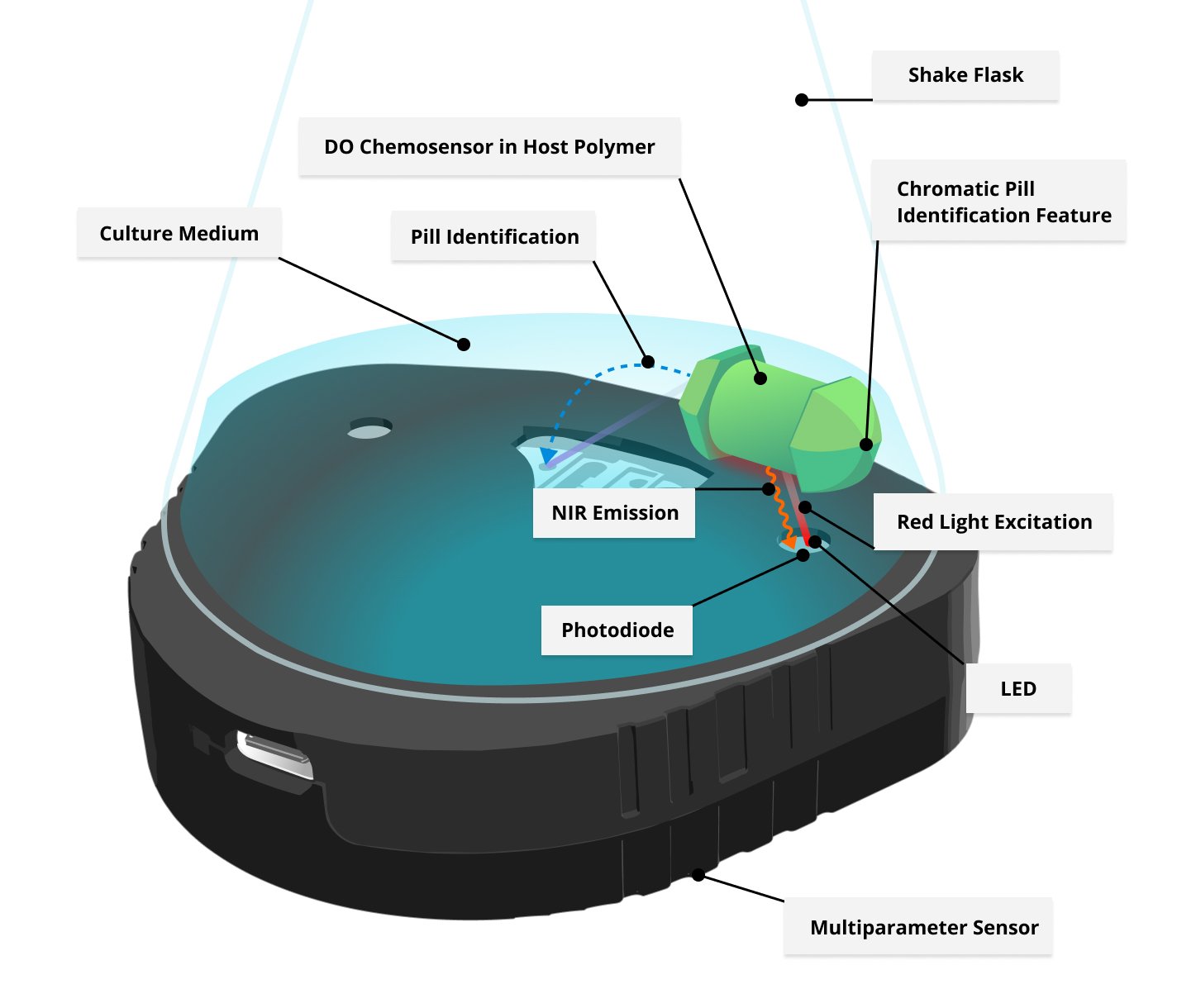

The Dissolved Oxygen Sensor Pills and Nanoparticles facilitate simplified, automated, and online DO monitoring in shake flasks. Mount your shake flask on top of the Multiparameter Sensor and add the DO Pill or Nanoparticles into your culture to start monitoring.

Key Features

Benefits

For a broad range of shaking speeds and filling volumes

Bioprocess characterization

Cell line/Strain development characterization and selection

Detect & avoid oxygen limitations

Collect critical process parameters for an informed upscaling process

Optimize process conditions with DO-based feeding

The DO Sensor is dropped into the shake flask which is then mounted on top of the MPS in the shaker. The pill is coated with a luminescent dye capable of detecting changes in dissolved oxygen (DO).

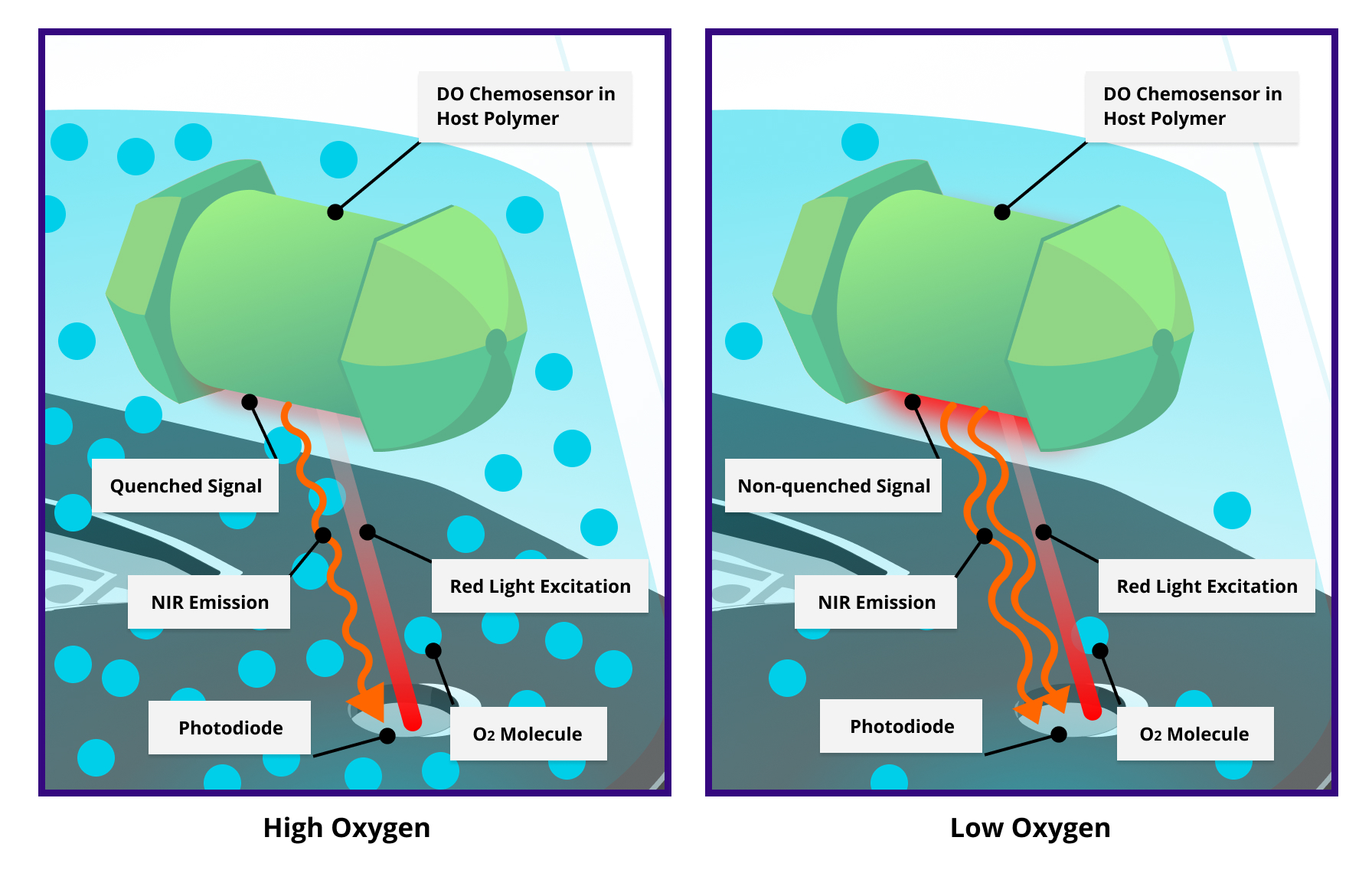

The sensor emits a red light (orange-red at a wavelength of 610-630 nm), exciting the chemosensors which show luminescence in the near-infrared region (NIR, 760-790 nm). Depending on the level of DO present in the solution, the amount of luminescence changes.

The MPS measures this phase shift and sends the data to the DOTS Software.

At low concentrations of DO, there is less collision between oxygen molecules and the indicator dye, allowing for a brighter emission of NIR light. As the oxygen concentration increases, the rate of collision also increases. This collision quenches the luminescence of the oxygen-sensitive indicator, reducing the intensity and affecting the phase shift of NIR emission.

Escherichia coli (E. coli), 200 rpm/25 mm, 10 % filling volume, 250 ml flask, 37°C, LB Medium

Dissolved Oxygen (DO) is considered a critical proces parameter in bioprocessing. Oxygen limitations cannot be seen directly and can only be detected through close monitoring. DOTS makes it possible to easily monitor DO in shake flasks in real time.

Inoculation: 0.32 million cells / mL, Corning flask, 250 mL, 24% filling volume (60 mL), 185 rpm, 25 mm

The DO Sensor pills, together with the MPS, allow for simultaneous measurement of biomass and dissolved oxygen (DO) in Corning flasks, producing well-correlated data curves to easily monitor DO in shake flasks in real time.

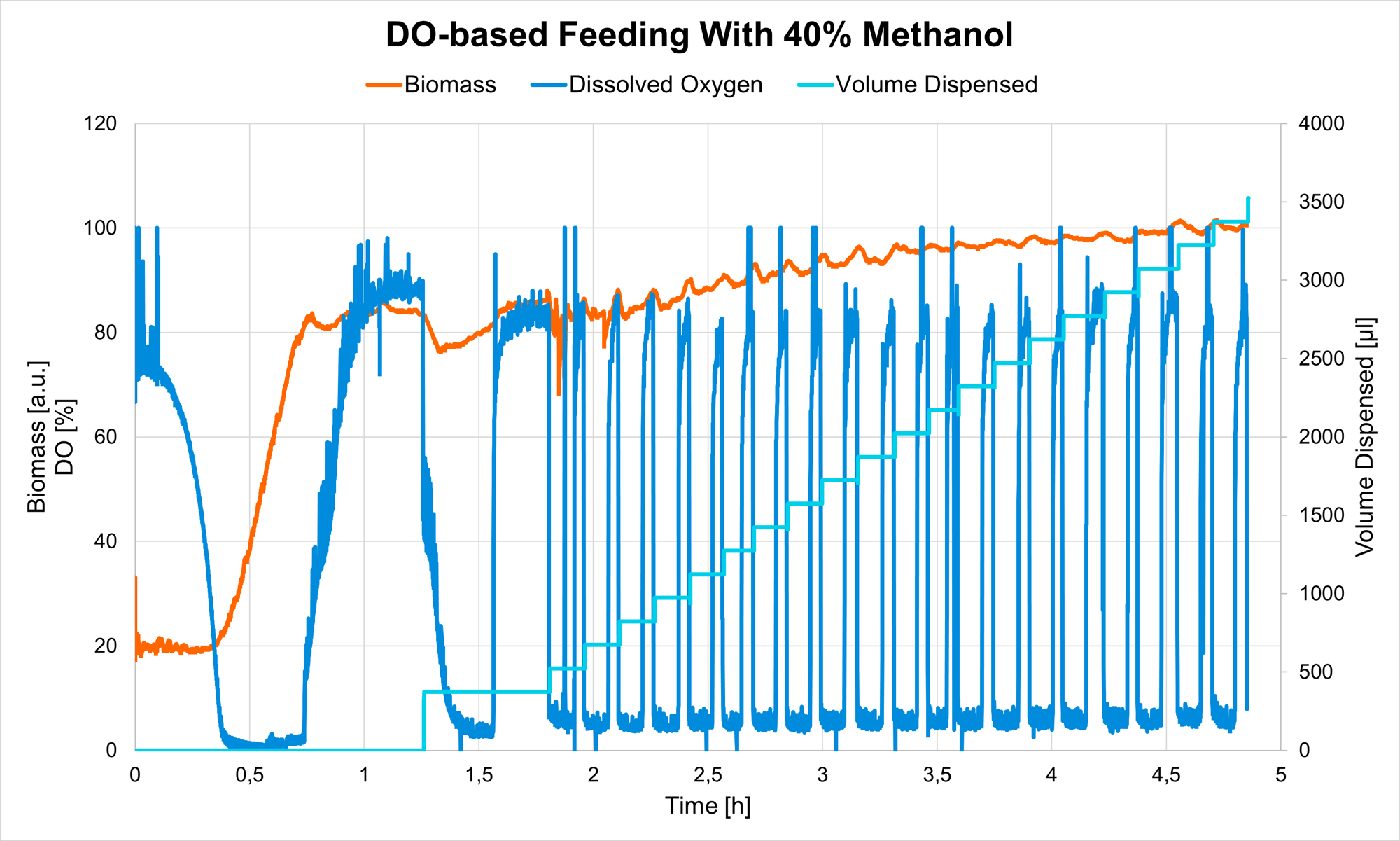

With a DOTS-integrated controller, the methanol feed (carried out with the Liquid Injection System) was adjusted to start repeatedly, always when the DO level, monitored by DO Sensor Pills, reached a preset threshold. By using this feature, methanol was always fed as soon as the cells recovered from the previous shot, enabling ideal cell viability, while keeping promotor activity constant. Biomass was monitored additionally, with the Multiparameter Sensor (MPS).

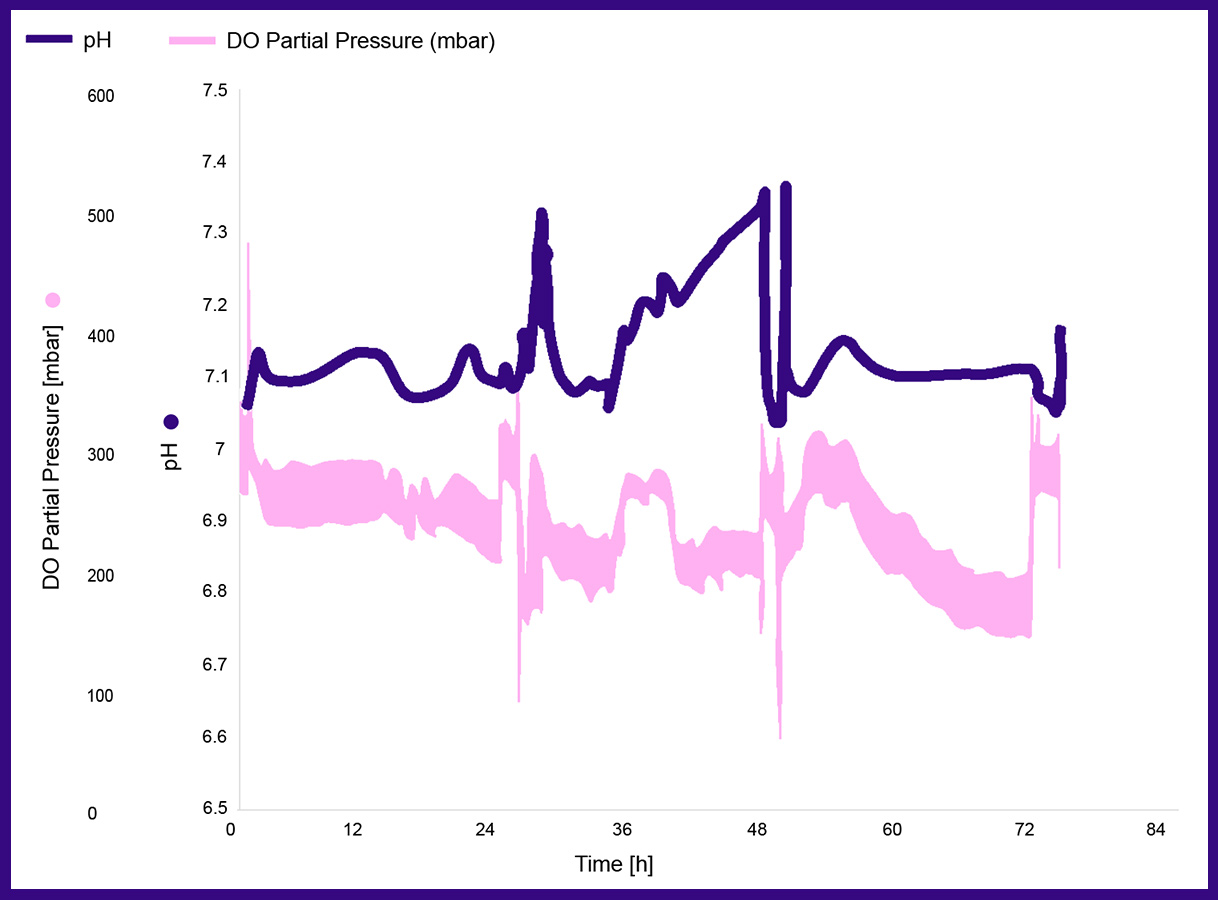

DO Nanoparticles enable precise dissolved oxygen measurements in both baffled and non-baffled shake flasks. Furthermore, evaluation of different cultivation conditions (10% vs. 20% fill volume) demonstrates strategies for optimizing bioprocess performance and mitigating oxygen transfer limitations.

Single-use sensor with an integrated chemosensor for dissolved oxygen measurements. Each sensor comes factory-calibrated and pre-sterilized so it is ready to use right out of the box. Broad portfolio of different sensor forms for different cell culture and microbial applications.

Non-invasive shake flask sensor capable of measuring DO and other parameters. The adapter holds the Multiparameter Sensor in place for increased stability, even at high shaking speeds.

DOTS Software, when paired with a sensor, enables the monitoring of critical parameters in real-time. Personalized dashboards allow you to easily visualize data while experimental control features facilitate the customized control of sensors and actuators. Important information such as calibration offsets and environmental compensation values (temperature, relative humidity, atmospheric pressure, and others) can be easily included.

"The DO Sensor Pills allow us to effortlessly visualize oxygen availability during shake flask cultivations. This important parameter has a strong influence on our overall process performance."

“The DO Nanoparticles enabled us to optimize our process parameters with regard to oxygen availability in our chosen baffled shake flasks. Having live information on this critical, previously inaccessible process variable for our standard protocols proved extremely helpful in evaluating process performance and adjusting parameters accordingly."

The Pill/Marble as well as the DO Nanoparticles are single-use products and should not be autoclaved or reused as they will loose their accuracy.

Specific leachables and extractables (L&E) tests have not yet been performed. However, in in-house tests with microbial cultures, we have not observed any leaching of material from the DO Pill.

The DO Pill introduces a small amount of shear stress to the culture, which may be relevant for experiments involving filamentous organisms. We have observed both intact and slightly altered morphologies in such cultures grown with the Pill.

Microbial growth on the DO Pill is extremely uncommon. In rare cases, our team has observed it with filamentous organisms. Under most bioprocess conditions, no growth on the Pill is expected.

The DO Pill does not. The DOTS Software can subtract the recorded Pill movement from biomass or fluorescence signals. Therefore, simultaneous measurement of DO, biomass, and fluorescence is not an issue with the Pill. The DO Nanoparticles influence standard turbidity measurements. For offline OD measurements, this effect can be compensated by always adding the relevant concentration of Nanoparticles, basically adjusting the blank. As for our scattered light readings, the sensitivity even for early growth and low biomass concentrations should not be influenced in a negative way, but a minor y-axis offset might be necessary when comparing a Nanoparticle cultivation with one without Nanoparticles.

You can choose between two units for displaying dissolved oxygen: % or mbar.

Our DO Sensor Pills have a shelf life of 6 months in their original packaging. The DO Nanoparticles have a shelf life of 3 months in their original packaging.

The DO Sensors are designed for reliable performance in long-term culture experiments. In practice, we have observed that the DO Pill maintains accurate and stable measurements for up to two weeks of continuous operation under typical culture conditions.

The Pill/Marble as well as the DO Nanoparticles are single-use products and should not be autoclaved or reused as they will loose their accuracy.

Specific leachables and extractables (L&E) tests have not yet been performed. However, in in-house tests with microbial cultures, we have not observed any leaching of material from the DO Pill.

The DO Pill introduces a small amount of shear stress to the culture, which may be relevant for experiments involving filamentous organisms. We have observed both intact and slightly altered morphologies in such cultures grown with the Pill.

Microbial growth on the DO Pill is extremely uncommon. In rare cases, our team has observed it with filamentous organisms. Under most bioprocess conditions, no growth on the Pill is expected.

The DO Pill does not. The DOTS Software can subtract the recorded Pill movement from biomass or fluorescence signals. Therefore, simultaneous measurement of DO, biomass, and fluorescence is not an issue with the Pill. The DO Nanoparticles influence standard turbidity measurements. For offline OD measurements, this effect can be compensated by always adding the relevant concentration of Nanoparticles, basically adjusting the blank. As for our scattered light readings, the sensitivity even for early growth and low biomass concentrations should not be influenced in a negative way, but a minor y-axis offset might be necessary when comparing a Nanoparticle cultivation with one without Nanoparticles.

You can choose between two units for displaying dissolved oxygen: % or mbar.

Our DO Sensor Pills have a shelf life of 6 months in their original packaging. The DO Nanoparticles have a shelf life of 3 months in their original packaging.

The DO Sensors are designed for reliable performance in long-term culture experiments. In practice, we have observed that the DO Pill maintains accurate and stable measurements for up to two weeks of continuous operation under typical culture conditions.

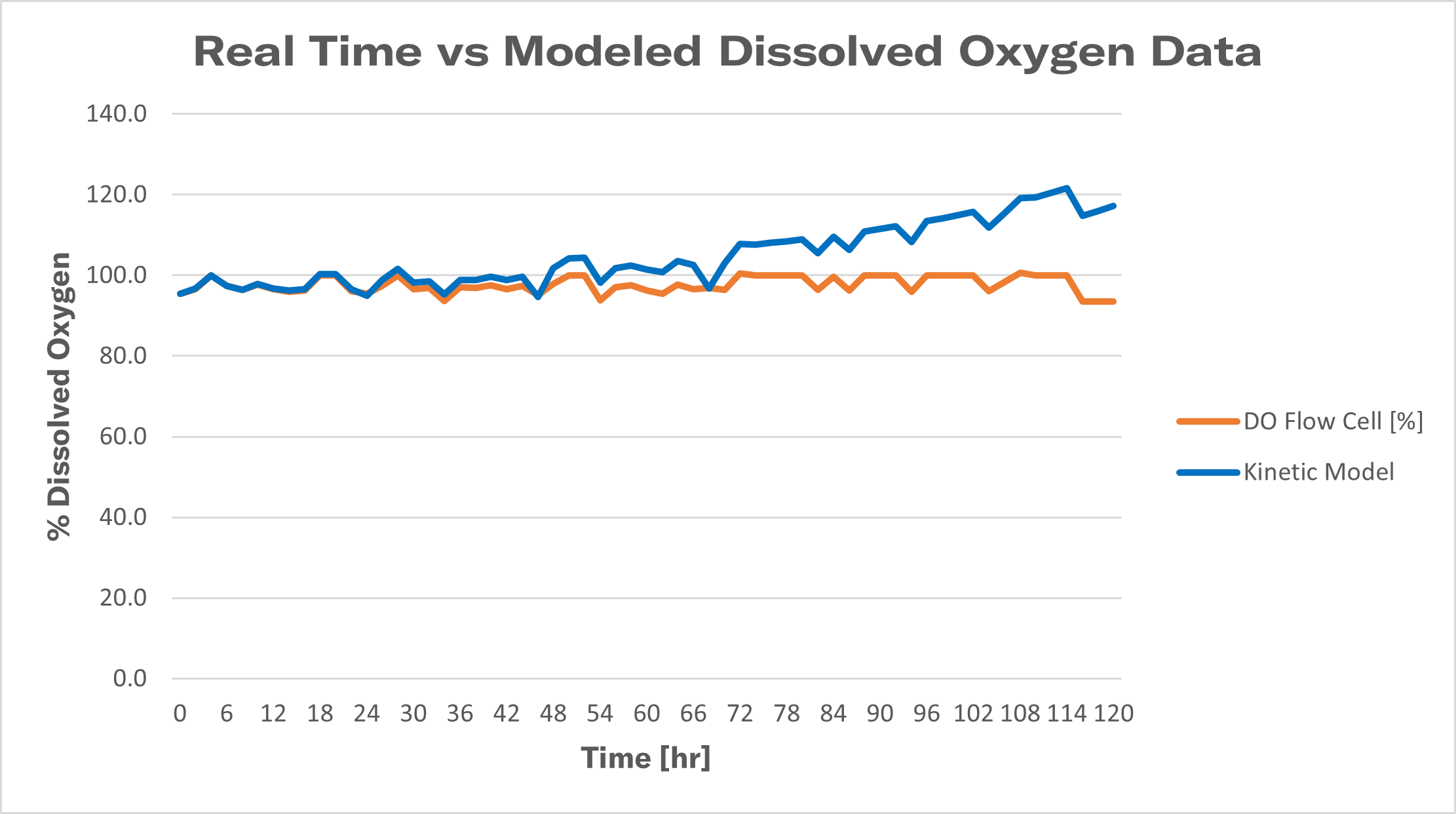

Integrated dissolved oxygen flow cells helped optimize a centrifugal bioreactor (CBR) designed to maximize cytotoxic T lymphocyte (CTL) production for use in immunotherapy treatments.