From Black Box Frustrations to Real-Time Data Control – Mastering the Timing of Manual Workflows

In the world of scientific research, it has been recognized that understanding bioprocesses is of utmost importance and at the same time one of the biggest challenges. The term "black box" is frequently used in discussions about bioprocesses, expressing the difficulty of peering into culture conditions and missing out on valuable information due to this lack of visibility. If a bioprocess would be self-regulating and -controlling, this would not be a problem. However, almost every microbial experiment necessitates multiple intervening steps where the scientist must manually withdraw samples, add liquids (like sugar solutions, nutrients, acids, bases, etc.), induce molecular processes, or harvest product or cells. All these processes depend on the right time - timing is essential! But how do you manage to look inside this black box and get the timing of your manual workflows right?

Expected Resolution: 5 Sample Points

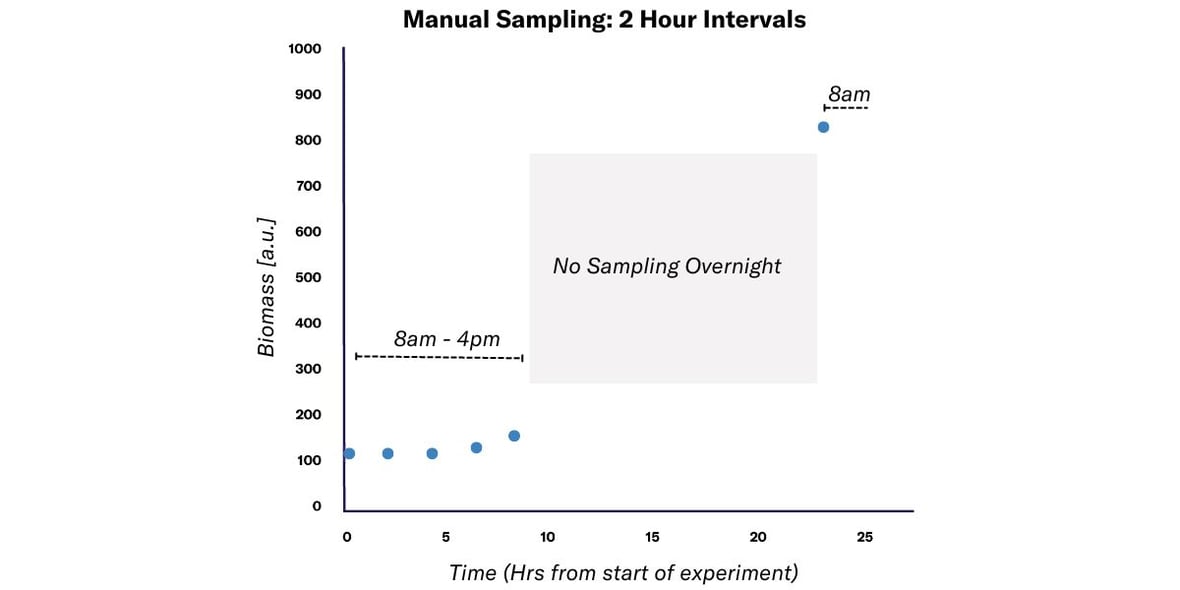

"If I just take a sample every few hours and measure the biomass, I can plot these data points over time and thereby generate a growth curve of my organism."

Hoping to gain knowledge about the exact growth status of their cells, the curious scientist therefore embarks on a systematic approach by continuously sampling biomass throughout the day with a convenient time interval of, for example, two hours. They then use their data to plot a growth curve revealing the organism’s development phase. With a two-hour interval, about 5 data points can be created during a normal workday, giving the scientist an estimate on when the ideal time point for e.g., cell harvest would be. However, biological systems are hard to predict – missed harvest windows are often the reality, thwarting the scientist's plans.

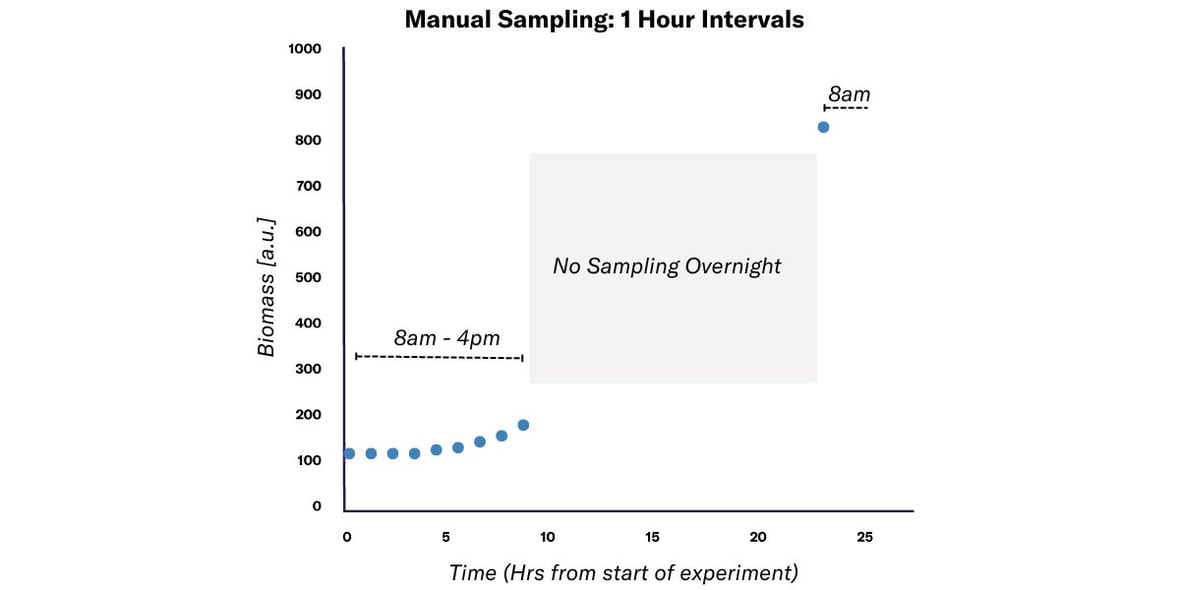

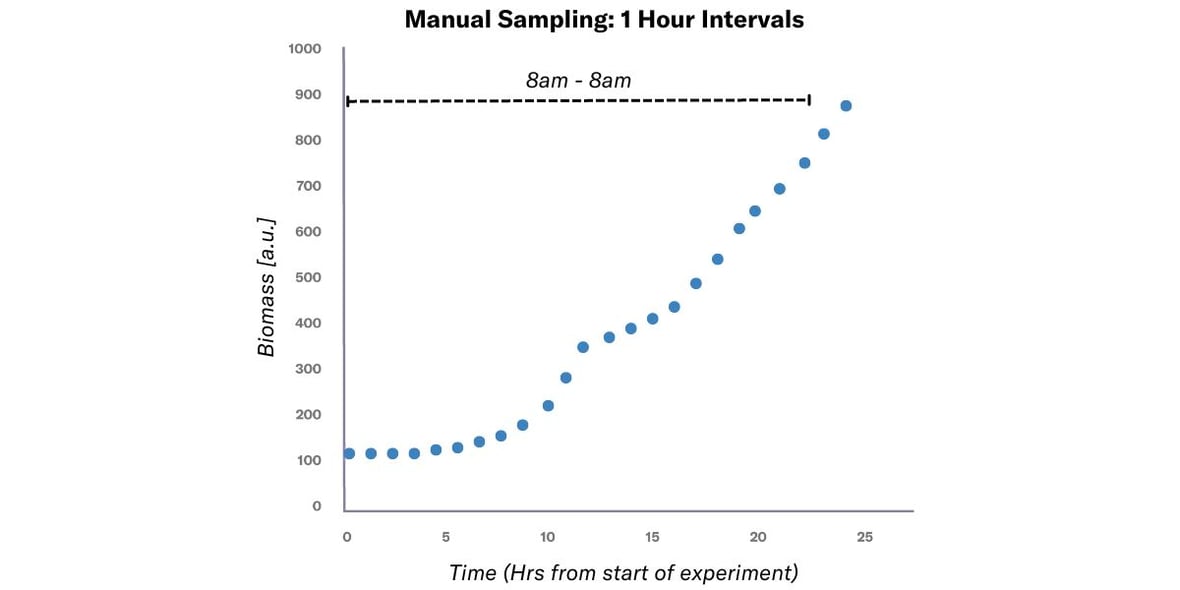

A diligent scientist would not give up just yet. Increasing the frequency of sampling to, for instance, every hour, extending lab hours to capture crucial data points, or even committing to an overnight presence – scientists display remarkable creativity and diligence, going the extra mile to achieve precise time points and optimize their experimental conditions. After all, great results make a happy scientist. But even after taking all these steps and investing over hours, it happens frequently that the ideal time points are still missed. Frustration constantly accompanies manual sampling.

Expected Resolution: 10 Sample Points

Expected Resolution: 24 Sample Points

And there are more disadvantages that must be considered when sampling manually and frequently. Each sampling usually necessitates the shaker being opened, disrupting the shaking movement. This reduces the oxygen availability to some extent and might temporarily change the temperature inside the shaker. The bioprocess is paused, and the cells no longer follow their growth behavior under optimal conditions. In addition, each sampling results in a reduction of the culture volume, making it necessary to account for each sampling step when setting up the experiment. For longer cultivations in which many samples are withdrawn throughout the cultivation time, this volume can become substantial. Adding more liquid to the culture to account for these samples, on the other hand, might reduce the oxygen transfer rate within the culture, at the beginning. Furthermore, although several data points are collected for an initial rough growth curve, significant time gaps between each sampling point still exist. Thus, the culture is still a black box, and the information content is low.

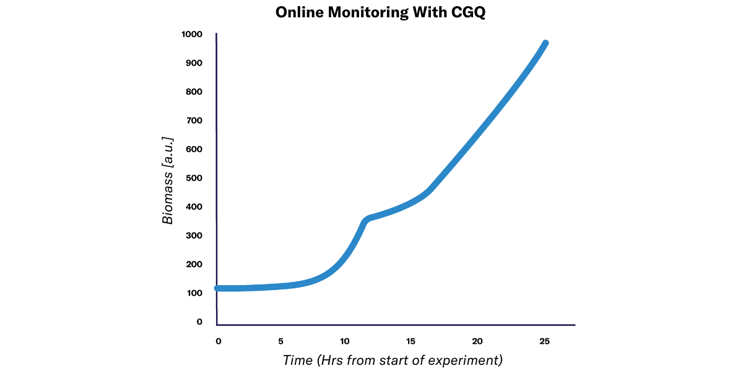

Expected Resolution: Sampling with the Cell Growth Quantifier (CGQ)

Sampling always comes at a cost and the experimenter must balance the negative consequences of each manual sampling on the culture as well as on their own workload with the benefit of having more data points, resulting in a more precise growth curve. There will never be a perfect solution with manual sampling. Applying sensors to gather high-density data sets in real-time can therefore be a real gamechanger for many experiments.

Our scientist starts their bioprocess all over again and this time they measure the biomass in real-time with this sensor. They no longer need to open a shaker to take a sample, and their culture volume remains constant. The real-time data processing offers actionable insights, and they can even monitor their culture from the office or from home, they do not have to stand in the laboratory all day. Goodbye night shifts and overtime!

They also find that real-time monitoring of their bioprocess opens many more possibilities. Not only is the timing of manual workflows easy and the workload significantly reduced, but they now have the tools at hand to detect diauxic shifts, oxygen limitations, substrate or product yields, or metabolite inhibitions, and even contaminations early-on and can intervene accordingly. With the help of the process-specific growth curve, they can understand and optimize their bioprocess and even control the production of desired products.

In conclusion, there is a way to remove black boxes. But the best work ethic and cleverest calculations or algorithms will not bring us there. Online sensors are a big help and a huge leap forward in optimizing the timing of manual workflows and thus enhancing culture conditions and experiment outcomes, especially in shake flask experiments.