The Role of Real-time Sensors in Benchtop Bioreactors

In recent years, bioprocessing has seen a rapid transformation thanks to the integration of advanced technologies that provide researchers and engineers with better control and more precise monitoring of microbial and cell culture processes. One of the key innovations in this field is the use of real-time sensors in benchtop bioreactors. These sensors offer fundamental insights into the critical parameters that govern biological reactions, driving efficiencies and improving outcomes across a range of applications.

What Are Benchtop Bioreactors?

A benchtop bioreactor is a scaled-down, laboratory-sized system designed to cultivate cells, microbes, or other biological systems in a controlled environment. These devices are commonly used in research and early-phase development for processes like protein production, fermentation, and cell culture. Benchtop bioreactors offer a more compact, cost-effective alternative to larger industrial systems while maintaining the essential functionalities required for high-quality bioprocessing.

Despite their smaller size, benchtop bioreactors need to precisely regulate multiple environmental and biochemical parameters such as temperature, pH, dissolved oxygen (DO), and nutrient concentrations. Maintaining proper conditions requires constant monitoring and the ability to make real-time adjustments.

The Growing Importance of Real-Time Sensors

In the past, manual sampling and off-line analysis were the standard methods of tracking bioprocess parameters. While these methods are valuable, they are inherently limited by their latency since data can only be gathered after a sample has been collected and analyzed, resulting in delayed feedback. This time lag can lead to suboptimal conditions or even failure to detect critical shifts in the culture environment, ultimately affecting the quality and yield of the bioprocess.

Enter real-time sensors which allow continuous, on-the-spot measurement of key parameters. These sensors provide data almost instantaneously, enabling bioprocess engineers to make timely decisions that can optimize culture conditions, improve process consistency, and boost product yields.

Types of Real-Time Sensors in Benchtop Bioreactors

Several types of sensors have become integral to benchtop bioreactor setups, each playing a role in monitoring specific variables. These include:

- Dissolved Oxygen (DO) Sensors

Oxygen is essential for aerobic cultures. DO sensors provide real-time readings of the oxygen levels in the culture medium, allowing operators to adjust gas flow rates or agitation speeds to ensure the cells or microbes receive adequate oxygen. Real-time monitoring of DO helps prevent oxygen depletion, which can lead to cellular stress and poor growth rates. - pH Sensors

The pH of a bioreactor’s culture medium is critical for maintaining optimal metabolic conditions. A shift in pH can significantly affect the activity of enzymes, proteins, and other biochemicals. Real-time pH sensors help to monitor and maintain stable pH levels by providing feedback that enables quick adjustments of acid or base additions. - Temperature Sensors

Temperature control is crucial in bioreactors, as too high or low a temperature can stress cells, decrease growth rates, or even kill them. Temperature sensors in benchtop bioreactors continuously track the thermal environment of the culture, allowing for rapid corrective actions such as adjusting the heating or cooling systems to maintain an optimal range. - Cell Density Sensors

These sensors measure the concentration of cells in the bioreactor, providing insight into the growth phase of the culture. Real-time cell density measurements can inform decisions about harvest times, batch completion, or adjustments to feeding strategies, all of which are critical for optimizing yield and productivity - Glucose and Nutrient Sensors

In cell culture, glucose and other nutrients are consumed by the growing cells and must be replenished as the bioprocess continues. Real-time nutrient sensors can provide valuable insights into the concentration of glucose, lactate, and other essential metabolites. By integrating these sensors with automated feeding systems, it’s possible to achieve closed-loop control, where nutrient addition is automatically adjusted based on real-time data.

Benefits of Real-Time Sensors in Benchtop Bioreactors

- Improved Process Control and Optimization

Real-time data from these sensors provide operators with a comprehensive view of the bioprocess conditions, allowing for more precise control. By detecting changes in parameters such as pH, DO, and temperature immediately, operators can make timely adjustments to optimize the environment for maximum cell growth, productivity, and product quality. - Increased Reproducibility

The ability to monitor and control variables in real time makes it easier to replicate experiments and industrial-scale processes with greater consistency. This reproducibility is particularly important in scaling up bioprocesses from the lab to pilot or commercial scales. - Enhanced Yield and Quality

By ensuring that all variables are kept within the optimal range, real-time sensors help prevent process deviations that could compromise the quality or yield of the final product. Whether it's optimizing cell growth for therapeutic protein production or fermentation for alternative proteins, real-time monitoring contributes to both higher product yields and improved product quality. - Faster Process Development

With real-time feedback, researchers can rapidly identify and address issues during experiments, accelerating the development of new bioprocesses and reducing the time it takes to bring new biotechnologies to market. Moreover, continuous data collection can also lead to more data-driven decision-making, helping researchers fine-tune processes for better outcomes. - Cost Efficiency

Although real-time sensor systems represent an initial investment, their ability to optimize bioreactor performance and reduce the likelihood of costly errors or product loss results in long-term cost savings. The automation enabled by these sensors can also reduce the need for manual labor and minimize the risk of human error.

Conclusion

The integration of real-time sensors into benchtop bioreactors represents a significant leap forward in bioprocessing, offering unparalleled control, efficiency, and optimization capabilities. By continuously monitoring and adjusting key parameters such as pH, temperature, oxygen, cell density, and nutrient concentrations, these sensors help ensure more consistent, reliable, and high-quality bioprocesses. As sensor technology continues to evolve, the potential for even greater advances in bioprocessing productivity and innovation is on the horizon, making real-time monitoring a critical tool for the future of biotechnology.

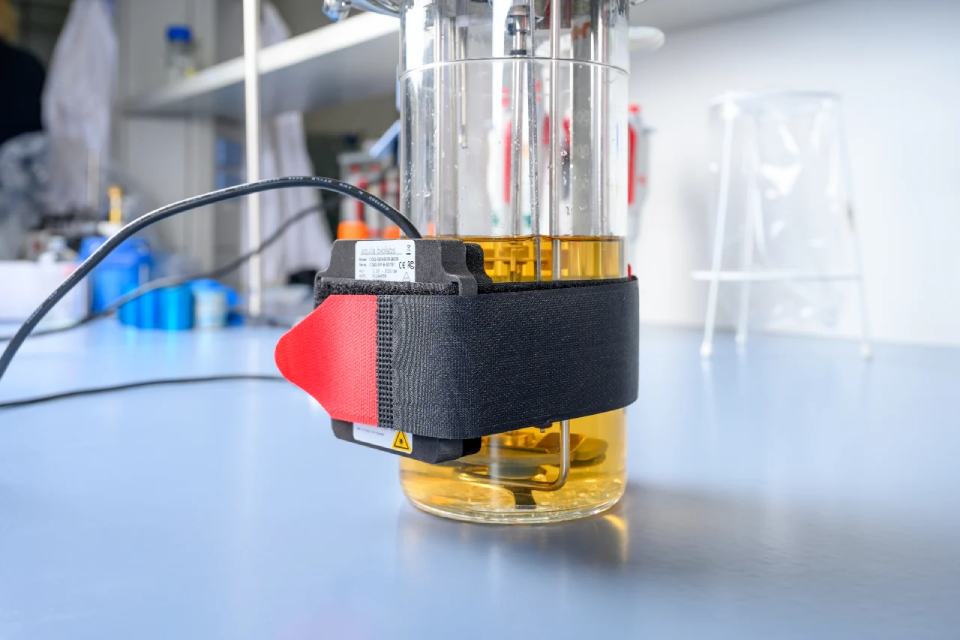

Learn how you can track your biomass using sbi’s non-invasive BioR technology!